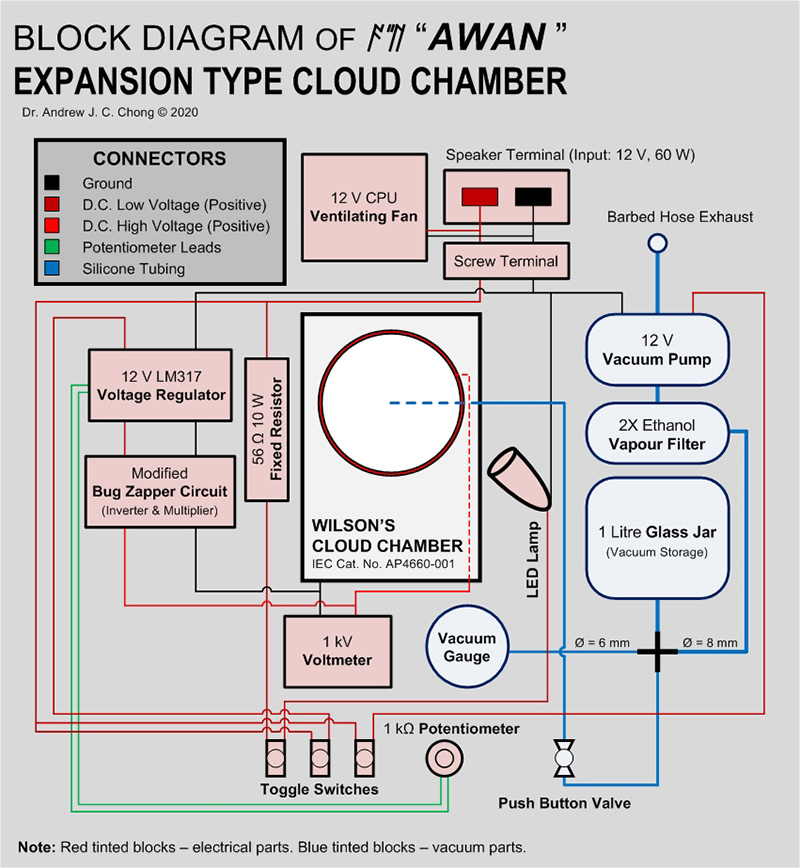

Photographs and specifications of finished assembly are available here. The entire assembly was modular, so not much testing was needed prior installation into the "black box". It is really more of electrical wiring than electronics. (wiring are shown in the schematics above). I now give a quick description of the vacuum system before going into the electrical part

A Vacuum System that Weans Off the Function of a Reverse Bicycle Tyre Pump

Earlier I had found sudden drop in pressure was able to achieve the same effect as volume expansion in this Wilson's cloud chamber. I used a homemade vacuum tank to store up a vacuum "charge"; a normally closed press-valve is connected directly from the tank to the chamber.

When the valve was pressed, the flow of gas from the chamber to the vacuum tank was able to reduce the pressure in the chamber fast enough (adiabatic) to achieve supersaturation with baric difference as low as -30 cmHg provided the inside of the chamber was pre-saturated with pure isopropyl alcohol. This was good news because I no longer have to depend on the reverse bicycle pump to achieve supersaturation.

During assembly, I included two ethanol vapour filters installed in series between the pump and the vacuum tank to avoid damage on the pump in prolonged operation. Even though the vapour of isopropyl alcohol (2-propanol) isn't acidic, I hope the addition of the filter might make AWAN last longer. Less servicing means more productivity.

Other safety features involving the vacuum system is that I have drilled air holes on the bottom of the box to provide ventilation, also an addition to the vacuum pump an exhaust vent so that the vapour can get out from the box directly instead of being trapped inside (together with high voltage circuit could potentially lead of explosive disaster in the event of a spark discharge).

The most important part during this assembly was figuring out the order of installation.

No comments:

Post a Comment